For detailed information, other images and documents, please select individual articles from the following table.

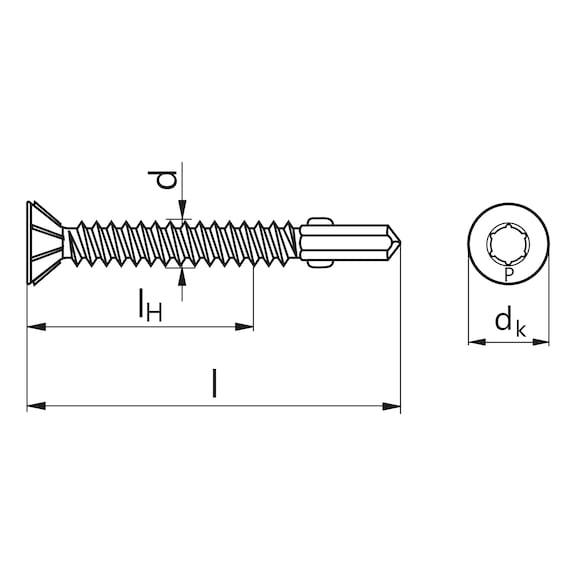

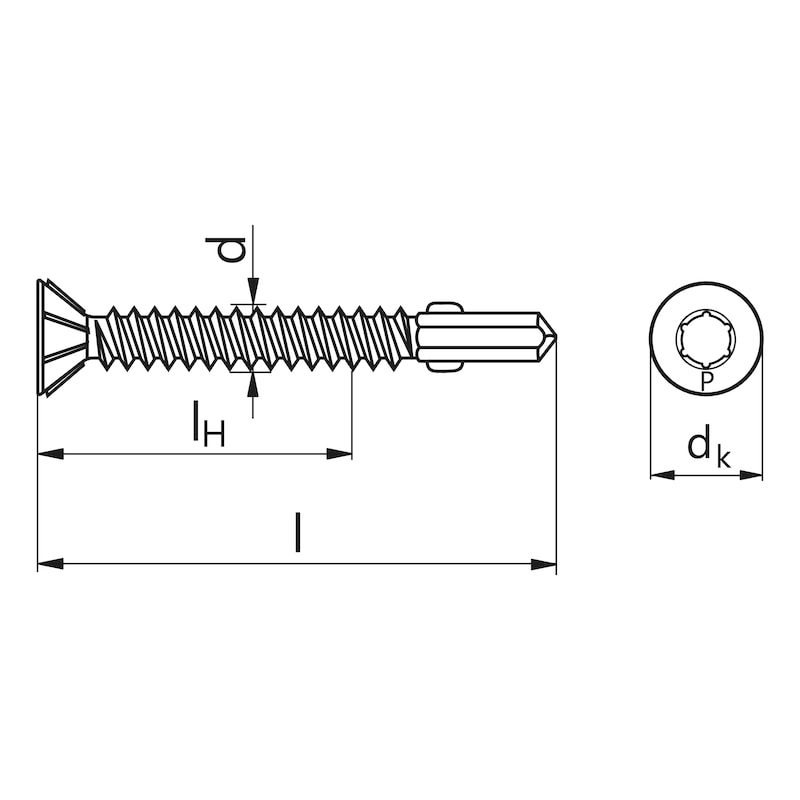

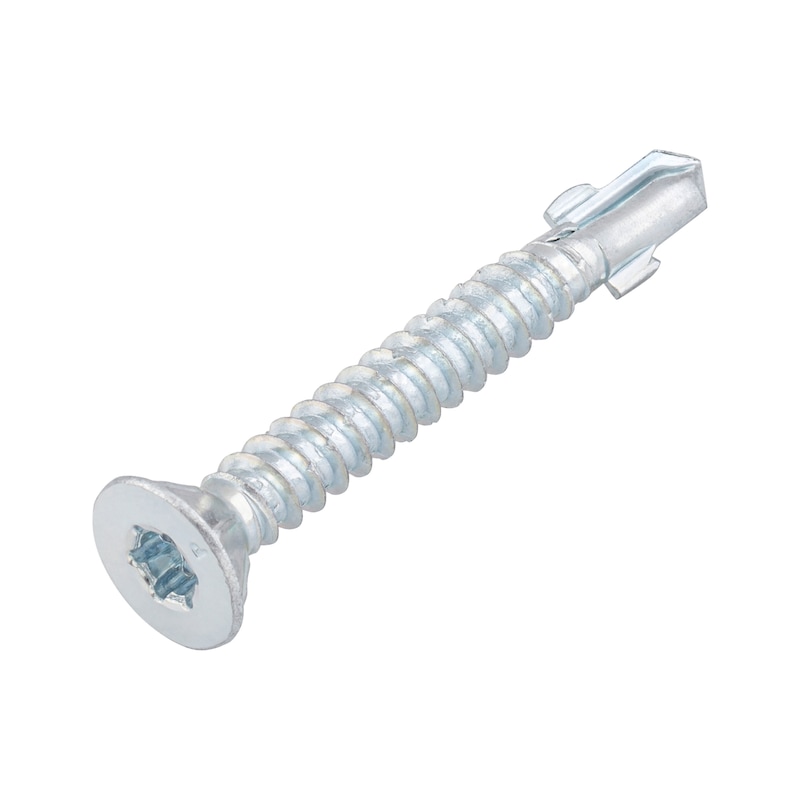

Wing-tip drilling screw with countersunk milling head With AW drive pias®

The self-drilling screw with up to 50% time savings when fastening wood to metal sub-structures

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Call customer service: 014/44.55.66

Prices for customers after login

Zinc-plated steel

With self-tapping thread

Countersunk milling head for use with hard and soft woods

AW drive system

- Enhanced torque transmission

- Longer life

- Optimum centring

- Better mounting output thanks to fatigue-free screwing in; the required contact pressure for transmission of the torques is considerably lower

- Largest possible contact surface of bit in screw drive

- Even force distribution prevents damage to the surface-protection coating and therefore ensures better resistance to corrosion

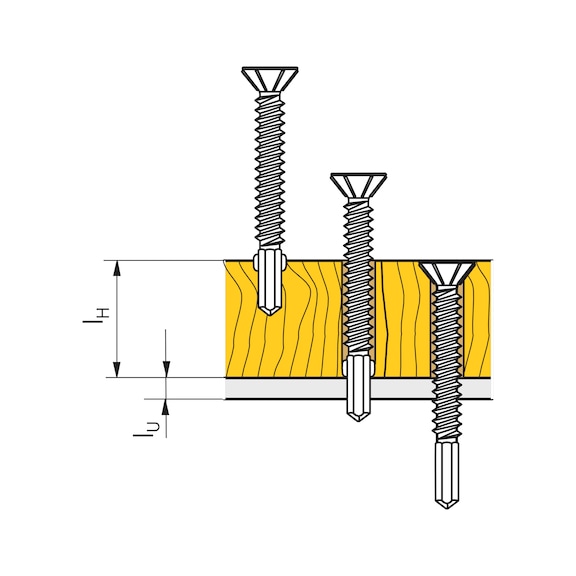

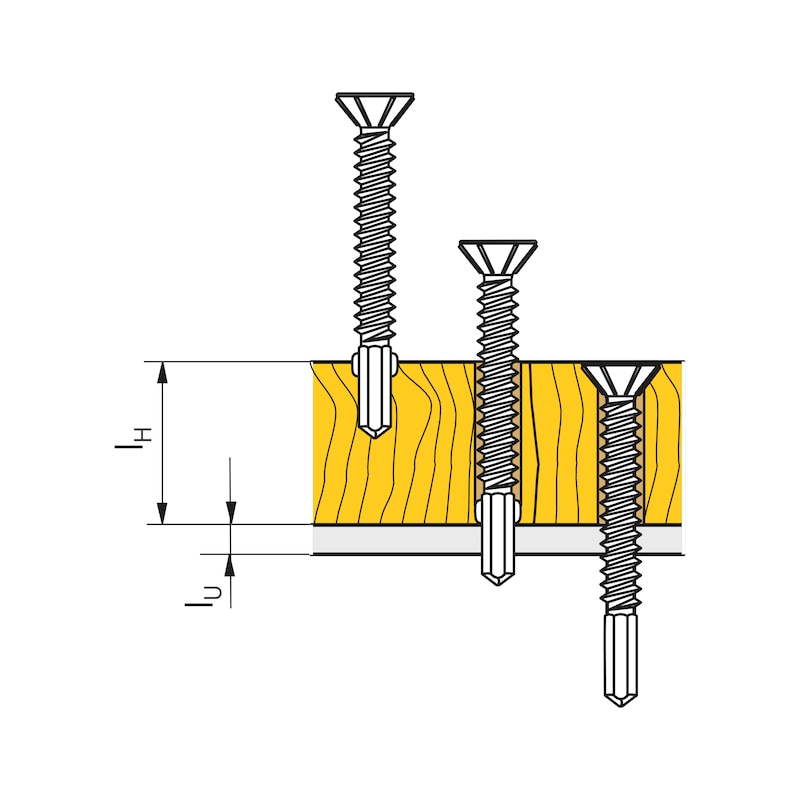

- The recommended maximum wood thickness lH was calculated with reference to the maximum attachment thickness lU of the surface!

- Wing-pias® screws must be appropriately tested for usability for each application case. Only install using application tools with a depth stop and claw coupling

- Drilling screws must be processed with a suitable drill driver (e.g. cordless drill driver with depth stop)

- The use of impact screwdrivers is not permitted

- Drilling screws must be attached perpendicular to the surface of the component

- Force feeding of the screw is prevented by the wings drilling out the wood

- The core hole is drilled into the substructure. The wings break off upon contact with the metal

- The first few turns of the screw cut the thread, the remainder of the screw then screws into the thread

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!