Solid carbide contour milling cutter, plastic, twin blade

Contour milling cutter SC WN Z2 type W GFRP/CFRP

CNTRMILCTR-WN-Z263-SC-D8,0MM

Art.-no. 5443301677

EAN 4055375924600

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 7986 |

Material to be processed | GRP |

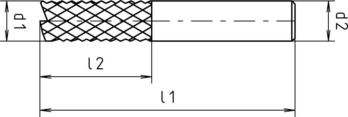

Diameter (d1) | 8 mm |

Shank diameter (d2) | 8 mm |

Standards | CS |

Shank style | Cylindrical |

Cutting material | SC |

Surface | Plain |

Coolant supply | External |

Length (l1) | 63 mm |

Cutting edge length (l2) | 25 mm |

Number of cutting edges (Z) | 2 PCS |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | FRP |

| Cutting values for finishing contour | |||||||||

| For dia. 2-14 | |||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||

| Dia. 2-3.9 | Dia. 4-5.9 | Dia. 6-7.9 | Dia. 8-9.9 | Dia. 10-11.9 | Dia. 12-14 | ||||

| Plastics | |||||||||

| GFRP/CFRP | - | - | 120 | 0,050 | 0,070 | 0,120 | 0,160 | 0,200 | 0,240 |

| Key |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae (radial cutting thickness) = 0.1xd1 |

| ap (axial cutting thickness) = 1.5xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |