For detailed information, other images and documents, please select individual articles from the following table.

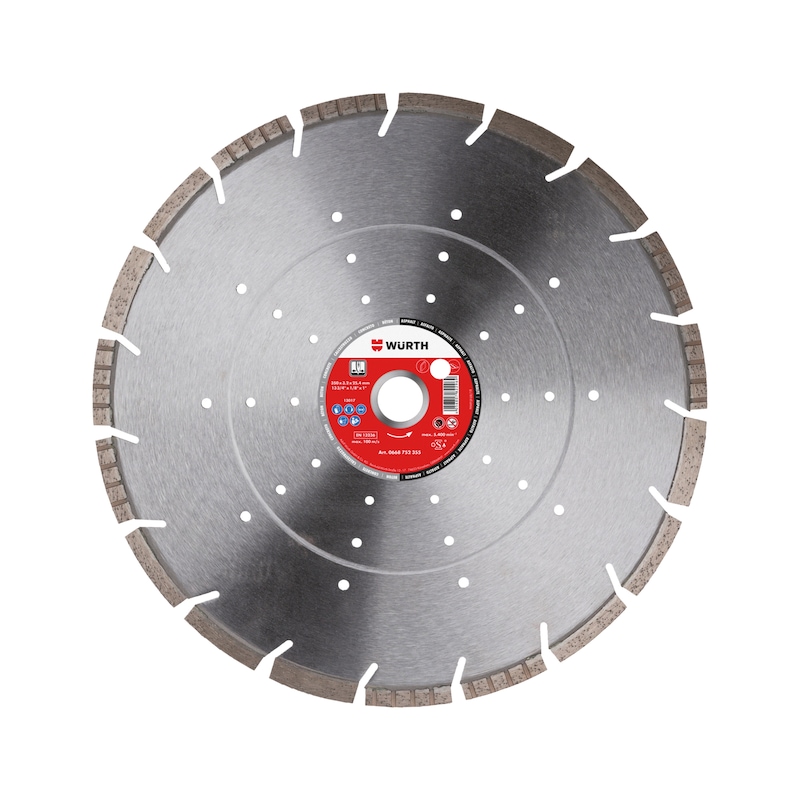

Diamond cutting disc Concrete/tarmac

Very versatile, durable and economical diamond cutting disc, though specially designed for tarmac, abrasive construction materials and concrete products

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Highly economical

- Very versatile due to alternating block and fan segments

- Optimum compromise between function and economy

- 10-mm segment height for good service life results

Protection against undercuts in the backing material in highly abrasive materials

Through specially arranged protection segments

- Diamond cutting discs become dull at excessively high speeds and wear too rapidly at insufficient circumferential speeds

- If the ease of cutting decreases (indicated by heavy sparking), resharpen the disc in abrasive material, e.g. sandstone, with several cuts

- Separate larger workpiece cross-sections in several sections (swing cut)

- Work without pressure — the weight of the machine is sufficient. Increased pressure causes increased wear.

- Diamond cutting discs are designed for straight cutting. Cutting curves deforms the blade and results in core cracks and segment tear-offs — risk of injury!

- Although the tool is safe, always wear safety goggles and clothing while working

- Observe the information on the label (max. speed), restrictions of use and safety instructions

- The direction arrow on the disc must match the machine's direction of rotation

- Must not be used for lateral grinding

- Use the appropriate protective hood

- Clamping must be performed only by a trained specialist (do not use force, use clean clamping flanges of the same size, perform a test run)

- If grinding tools are clamped or used incorrectly or are damaged, they represent a danger and may cause serious injury

- Particularly suitable for concrete (including reinforced concrete), exposed aggregate concrete, aerated concrete, tarmac, abrasive building materials, screed, brick, concrete roof tiles and Poroton

- For dry and wet cutting

- For use on manual cutting discs and floor saws

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!