Plastic frame anchor W-UR F 8, galvanised steel

Plastic frame anchor W-UR F8 steel zp pan head

ANC-(W-URF/PH)-PLA-AW30-(A2K)-30/10-8X80

Art.-no. 0912808803

EAN 4047376505469

Register now and access more than 125,000 products

- With pan head screw, galvanised steel

- Pass-through mounting

- Immediate load-bearing capacity, no waiting

- Low anchor screw insertion torque → slight spreading of the anchor with virtually no movement of the anchor sleeve

- 2 insertion depths (hnom = 50 + 70 mm): Concrete >= C12/15; solid brick >= Mz 10 (>= NF); hollow brick >= HLz 8 (>= 2DF); solid sand-lime brick >= KS 10 (>= NF); perforated sand-lime brick >= KS L 6 (>= 2DF); perforated sand-lime brick >= KS L 6 (>= 12DF); standard solid concrete brick >= Vbn 10 (>= NF); solid lightweight concrete brick >= V 2 (>= NF)

- Expands in four directions: high load-bearing capacity

- Optimal force transmission: Even, continuous load distribution across the entire expansion area

- Universal frame anchor (concrete, hollow brick, solid brick, masonry and autoclaved aerated concrete)

- Hammer-in stop prevents premature expansion of the anchor during installation

- Special pre-assembled anchor and screw for easier installation

- Type W-UR F anchor does not require an additional U-washer and prevents contact corrosion

- Improved load transfer in solid and hollow construction materials; anchorage via friction locking between anchor sleeve and anchoring base

W-UR 8 and W-UR F 8 (galvanised steel, stainless steel): European technical approval ETA-08/0190

High-quality polyamide anchor sleeve

Fire resistance W-UR 8: Concrete: Tensile and transverse loads, R30, R60, R90, R120 (according to technical report TR 020) Tensile load in masonry: F30 (solid sand-lime brick, solid brick, perforated sand-lime brick) Transverse load: F30, F60, F90, F120 (hollow brick, perforated sand-lime brick, solid brick, autoclaved aerated concrete)

Notice:

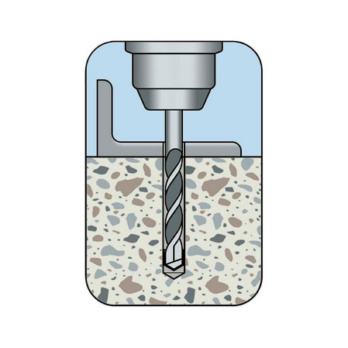

Drill perforated and hollow blocks with a rotary drill (without impact mechanism)

For anchoring in solid brick and solid sand-lime brick, we recommend that you perform pull-out tests due to the differences in brick manufacturing.

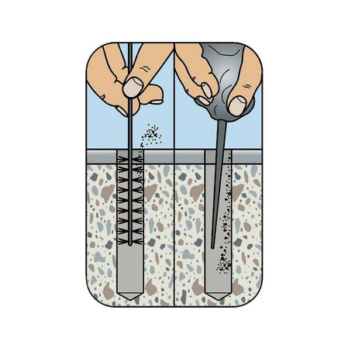

Debris must be removed from the drill hole

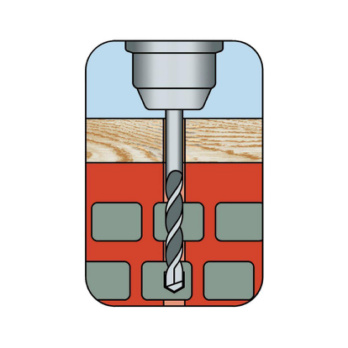

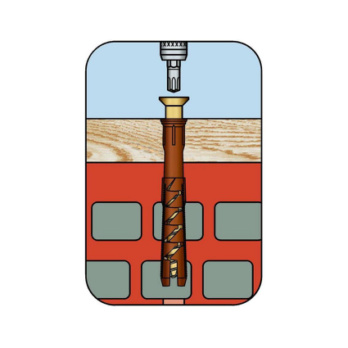

Create the drill hole

Create the drill hole

Clean the drill hole

Clean the drill hole

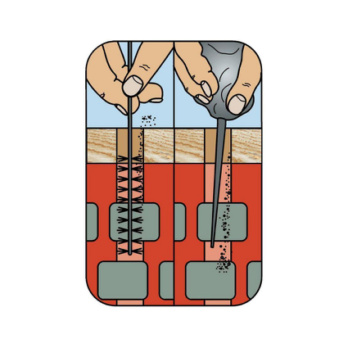

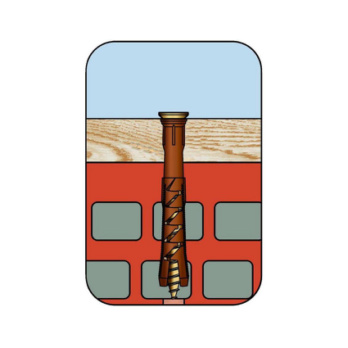

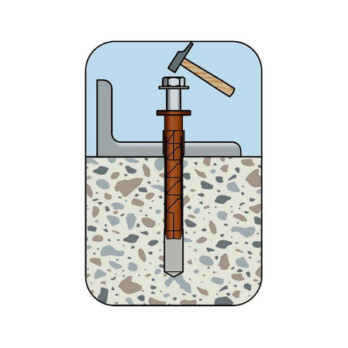

Set anchor and screw

Set anchor and screw

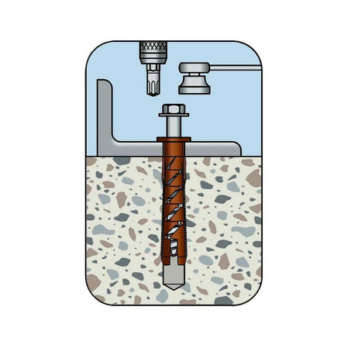

Screw in the screw

Screw in the screw

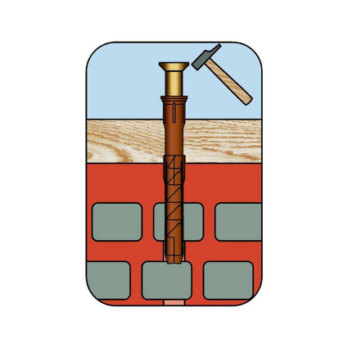

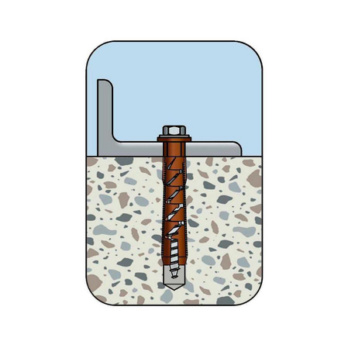

Screw in screw until flush

Screw in screw until flush

Create the drill hole

Create the drill hole

Clean the drill hole

Clean the drill hole

Set anchor and screw

Set anchor and screw

Screw in the screw

Screw in the screw

Screw in screw until flush

Screw in screw until flush

Datasheets(X)

The anchor has European technical approval for use in multiple connections of non-load-bearing systems (e.g. frames, suspended ceilings etc.).

W-UR and W-UR F can be anchored in the following anchor bases: Standard concrete, masonry walls (solid brick, solid sand-lime brick, hollow brick, perforated sand-lime brick, hollow lightweight concrete blocks, solid bricks and solid lightweight concrete blocks, concrete bricks, autoclaved aerated concrete), brick ceilings, prestressed hollow concrete slabs, reinforced autoclaved aerated concrete, plasterboard wall panels

Installation temperatures:

Anchor base temperature: >= -40 °C

Anchor sleeve temperature: >= 0 °C

The galvanised screw can be used outdoors or in damp spaces (with careful installation) if the area around the screw head is protected from moisture or rain, so moisture does not penetrate the anchor shaft (suitable paint)

Suitable for attaching frames, ceilings and ceiling substructures (made of wood or steel), wooden beams, wooden slats, metal brackets, metal rails, suspended ceilings, cable ducts, angle brackets, profiles, wall-mounted cabinets, shelves etc.

Anchor diameter | 8 mm |

Anchor length (l) | 80 mm |

Nominal drill-bit diameter (d 0) | 8 mm |

Through-hole in the component to be connected (d f) | 8.5 mm |

Attachment height (t fix 1) | 30 mm |

Material of screw | Steel |

Internal drive | AW30 |

Surface of the screw | Zinc plated |

Head type | Pan head |

Approval | ETA-08/0190 |

Type description | W-UR F 8, pan head screw |

| Characteristic values for installation in concrete and masonry | ||||

| Anchor diameter [mm] | W-UR 8 | |||

| Nominal drill diameter | d0 [mm] | 8 | ||

| Diameter of cutting edges | dcut ≤ [mm] | 8,45 | ||

| Drill hole depth | h1 ≥ [mm] | 607) | 80 | |

| Embedment depth of the anchor sleeve | hnom [mm] | 507) | 70 | |

| Through hole in the attachment | df ≤ [mm] | 8,5 | Concrete: ETA-08/0190, anchors in a redundant non-structural system in non-load-bearing systems | |

| Anchor diameter [mm] | W-UR 8 | |||

| Centric tension load1) for individual anchors or anchor group | Nadm = C12/15 [kN] | 30°C2)/50°C3) | 1,2 | 1,6 |

| 50°C2)/80°C3) | 1,0 | 1,4 | ||

| Nadm ≥ C16/20 [kN] | 30°C2)/50°C3) | 1,6 | 2,4 | |

| 50°C2)/80°C3) | 1,4 | 2,0 | ||

| Shear load1) Stainless steel A4 for individual anchor or anchor group | Vadm ≥ C12/15 [kN] | 3,37 | 3,37 | |

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. For the combination of tensile and shear loads, please refer to ETAG 020 Appendix C. 2) Maximum long-term temperature. 3) Maximum short-term temperature. 7) 2. Embedment depth applies to the following base materials: Concrete ≥ C12/15; Solid brick ≥ Mz 10 (≥ NF); Vertically perforated brick ≥ HLz 8 (≥ 2DF); Solid calcium silicate block ≥ KS 10 (≥ NF); Hollow calcium silicate block ≥ KS L 6 (≥ 2DF); Hollow calcium silicate block ≥ KS L 6 (≥ 12DF); Solid bricks made of normal weight concrete ≥ Vbn 10 (≥ NF); Solid bricks made of lightweight concrete ≥ V 2 (≥ NF). | ||||

| Anchor sizes | |||||||

| Anchor diameter | [mm] | W-UR 8 | |||||

| Total length | l [mm] | 60 | 80 | 100 | 120 | 140 | 160 |

| Max. fixture thickness, hnom= 50 mm7) | tfix [mm] | 107) | 307) | 507) | 707) | 907) | 1107) |

| Max. fixture thickness, hnom= 70 mm | tfix [mm] | - | 10 | 30 | 50 | 70 | 90 |

| 7) 2. Embedment depth applies to the following base materials: Concrete ≥ C12/15; Solid brick ≥ Mz 10 (≥ NF); Vertically perforated brick ≥ HLz 8 (≥ 2DF); Solid calcium silicate block ≥ KS 10 (≥ NF); Hollow calcium silicate block ≥ KS L 6 (≥ 2DF); Hollow calcium silicate block ≥ KS L 6 (≥ 12DF); Solid bricks made of normal weight concrete ≥ Vbn 10 (≥ NF); Solid bricks made of lightweight concrete ≥ V 2 (≥ NF). | |||||||

| Masonry4): ETA-08/0190, anchors in a redundant non-structural system in non-load-bearing systems (temperature range 50°C2)/80°C3))For other types of stone, raw densities, minimum pressure strengths or temperature ranges, please refer to the approval ETA-08/0190. | |||||

| Brick format [mm] | Raw density class [kg/dm³] | Minimum compressive strength [N/mm²] | Fadm [kN]5) (for individual anchors or anchor group) W-UR 8 hef= 50 to 69 mm/ hef= 70 mm | ||

| Masonry brick Mz, EN 771-1, DIN 105 | ≥ NF (≥ 240 x 115 x 71) | ≥ 1.8 | 28 | 0,71 | 0,86 |

| 36 | 1,0 | 1,14 | |||

| Solid calcium silicate block KS, EN 771-2, DIN 106 | ≥ NF (≥ 240 x 115 x 71) | ≥ 2.0 | 10 | 0,43 | 0,43 |

| 20 | 0,57 | 0,71 | |||

| 28 | 0,86 | 1,0 | |||

| Solid brick normal weight concrete Vbn, EN771-3, DIN 18152 | ≥ NF (≥ 240 x 115 x 71) | ≥ 2.0 | 10 | 0,43 | 0,43 |

| 20 | 0,71 | 0,71 | |||

| 28 | 1,0 | 1,0 | |||

| Vertically perforated brick HLz6), EN 771-1, DIN 105-1 e.g. Wienerberger, Schlagmann | ≥ 2DF (≥ 240 x 115 x 113) | ≥ 1.2 | 8 | 0,14 | 0,21 |

| 12 | 0,21 | 0,26 | |||

| 20 | 0,34 | 0,43 | |||

| Vertically perforated brick POROTON S11-36.56), EN 771-1, Z-17.1-812 Wienerberger, Schlagmann | ≥ 248 x 365 x 249 | ≥ 0.9 | 6 | - | 0,57 |

| Vertically perforated brick UNIPOR WS14, UNIPOR WS12 CORISO EN 771-1, Z-17.1-883 Unipor-Ziegel Marketing GmbH | ≥ 10DF (≥ 247 x 300 x 249) | ≥ 0.8 | 10 | - | 0,17 |

| 12 | - | 0,21 | |||

| Hollow calcium silicate block KSL6), EN 771-2, DIN 106-1 e.g. Xella | ≥ 2DF (≥ 240 x 115 x 113) | ≥ 1.6 | 10 | 0,26 | 0,57 |

| 12 | 0,26 | 0,71 | |||

| 16 | 0,34 | 0,71 | |||

| ≥ 8DF (≥ 249 x 240 x 238) | ≥ 1.4 | 10 | - | 0,26 | |

| 12 | - | 0,34 | |||

| 16 | - | 0,43 | |||

| Hollow concrete block made of lightweight concrete 3K Hbl, EN 771-3, DIN 181516) e.g. Liapor | ≥ 16DF (≥ 498 x 240 x 238) | ≥ 0.7 | 2 | - | 0,11 |

| 4 | - | 0,26 | |||

| 6 | - | 0,34 | |||

| Hollow concrete block made of lightweight concrete Liapor-Super-K6), EN 771-3, Z-17.1-501 | ≥ 16DF (≥ 495 x 240 x 238) | ≥ 0.8 | 2 | - | 0,17 |

| 4 | - | 0,34 | |||

| Autoclaved aerated concrete (AAC) | 2 | - | 0,14 | ||

| 7 | - | 0,85 | |||

| 2) Maximum long-term temperature. 3) Maximum short-term temperature. 4) For other types of stone, raw densities, minimum pressure strength or temperature ranges, please refer to the approval ETA-08/0190. 5) The brick geometry should be compared with approval ETA-08/0190. 6) If the drill hole is created through impact or hammer action, the admissible load must be determined through tests on the structure. | |||||