EPDM butyl outdoor sealing tape, 0.8 mm

EPDM butyl outdoor sealing tape, 0.8 mm

SEALTPE-RAL-OUTS-EPDM/BUTYL-0,8X200X20M

Register now and access more than 125,000 products

Material saving as 0.8 mm thickness meets the same requirements as 1.2 mm thickness

- Better economy

- More simple and flexible processing, e.g. in corners

- Improved sustainability through resource savings

Waterproof and breathable

- Provides reliable seal against water from outdoors

- At the same time, the membrane has sufficient diffusion permeability to allow water vapour from indoors to diffuse outdoors, thereby preventing moisture-related damage to buildings

- Thanks to its high-quality material, the EPDM film remains permanently sealed and compensates particularly well for component movements

- Its high weathering resistance makes the EPDM film ideally suited for permanently secure sealing

- Reliable installation is also achieved on slightly uneven construction surfaces, when combined with SMP EPDM adhesive sealing tape.

- Good compatibility with bitumen

- Not suitable for seals according to water influence classes W2.2-E (high influence from pressurised water ≥ 3 m immersion depth).

- Tape cannot be plastered over.

Datasheets(X)

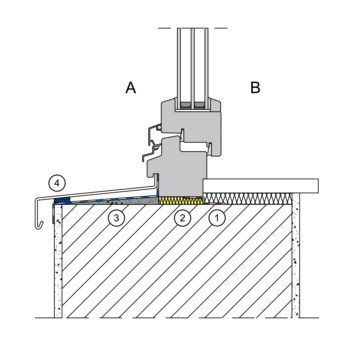

Permanent, reliable sealing of joints outdoors, e.g. for window sills, floor-level windows and balcony doors, for outside door sills, conservatories and in façade area.

- Wall barrier sheet

- Joints behind perimeter insulating materials

- Corresponds to the following water influence classes from DIN 18533:

- W1.1-E: Floor moisture and non-pressurised water for floor panels and walls in contact with the ground

- W1.2-E: Floor moisture and non-pressurised water for floor panels and walls with drainage in contact with the ground

- W1-E: External sealing on ceiling surfaces covered with earth and not traversed, with soil moisture and non-pressurised water – non-standing seepage water

- W2.1-E: Moderate influence from pressurised water ≤ 3 m immersion depth

- W4.E: Spray water on the wall socket as well as capillary water in and under walls in contact with the ground

- The surfaces must be dry, dust-, grease- and ice-free and capable of bearing loads. We recommend cleaning the elements with Activating Cleaner surface cleaner.

- Installation: Cut the EPDM tape to the required length. Apply the SMP EPDM adhesive sealing tape to the surface and wipe off with a spatula. The thickness of the adhesive layer should be 1 mm. Glue the EPDM tape to the surface and press on lightly using a press-on roller, while ensuring tension-free installation.

- The butyl self-adhesive tape is used as a mounting aid on the frame/element and the tape must be secured with a mechanical fixing in accordance with DIN18533.

| |

Colour | Black |

Backing material | EPDM |

Adhesive base | Butyl |

Chemical basis | Ethylene propylene diene natural rubber |

Width | 200 mm |

Thickness | 0.8 mm |

Length of roll | 20 m |

Design | With butyl adhesive strip |

Water-vapour diffusion resistance (description) | Inside more impermeable than outside |

Min./max. processing temperature | -5 to 35 °C |

Min./max. temperature resistance | -30 to 75 °C |

Building material class/conditions | B2 - Normally inflammable / in accordance with DIN 4102 |

Ultraviolet resistance | Yes |

Max. water-vapour diffusion resistance factor value µ | 5882 |

Elongation at break | 300 % |

Resistance against | Bitumen |

Shelf life from production/conditions | 12 Month / at 5°C to 30°C |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!