BoxBolt® hollow profile fastener A4 stainless steel. The mechanical material properties of the screws correspond to strength class 70 in accordance with DIN EN ISO 3506-1.

BoxBolt hexagon stainless steel A4

HLSECTFSTNR-BOXBOLT-(6-35)-A4-M16

Register now and access more than 125,000 products

Never exceed the permissible working loads. Before using hollow section fasteners, always check that the steel structure can withstand the required loads.

Datasheets(X)

For fastening to hollow sections or other hard-to-reach components. The fastener is especially suitable for applications where the installation point is only accessible from one side.

The connection is produced by tightening the screw while bracing the sleeve collar, resulting in expansion of the sleeve. The tightening torques can be applied using a torque spanner. The hollow section fastener is only approved for one-time use!

We recommend the BoxSokTM special tool for installation.

| |

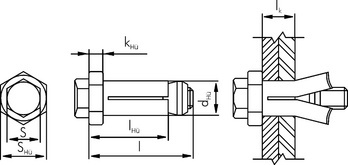

Thread type x nominal diameter | M16 |

Screw length (l) | 75 mm |

Width across flats (S) | 24 mm |

Width across flats, sleeve (SHü) | 36 mm |

Sleeve diameter (dHÜ) | 25.5 mm |

Collar thickness (kHü) | 9 mm |

Sleeve length (lHü) | 61 mm |

Min./max. grip length (lk) | 6-35 mm |

Nominal drill hole diameter | 26 mm |

Tightening torque | 190 Nm |

Min. hole distance (A) | 55 mm |

Min. edge clearance (B) | 20 mm |

Material | Stainless steel A4 |

Surface | Plain |

RoHS-compliant | Yes |

| Nominal diameter | Maximum working load in kN1 | |

| A4 stainless steel | ||

| Permissible tensile load | Permissible shear load | |

| Ft,adm.1 | Fv,adm.1 | |

| M8 | 13,29 | 26,14 |

| M10 | 21,07 | 47,07 |

| M12 | 30,64 | 59,86 |

| M16 | 57,07 | 108,57 |

| M20 | 89,28 | 182,14 |

| 1Working loads Ft,adm. = Ft,R,d/γF or Fv,adm. = Fv,R,d/γF (partial safety factor of the effects γF = 1.4). In cases of the simultaneous occurrence of tensile and shear forces, observe the information in DIN EN 1993-1-8, table 3.4. | ||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!